ISO Certification:

![]() Inside Track Cabling (ITC) has achieved and maintains ISO9001-2015 Certification to the International Quality Management System Standard. This certification demonstrates ITC’s company-wide commitment to quality in every aspect of manufacturing from conception and design throughout the product realization and delivery process. ISO certification is recognized worldwide as an accepted standard of process quality. We use the ISO standard to document and measure the effectiveness of our quality system, and in turn to monitor our progress toward the continual improvement of our products, systems and services.

Inside Track Cabling (ITC) has achieved and maintains ISO9001-2015 Certification to the International Quality Management System Standard. This certification demonstrates ITC’s company-wide commitment to quality in every aspect of manufacturing from conception and design throughout the product realization and delivery process. ISO certification is recognized worldwide as an accepted standard of process quality. We use the ISO standard to document and measure the effectiveness of our quality system, and in turn to monitor our progress toward the continual improvement of our products, systems and services.

Inside Track Cabling QMS Certificate

UL Certification:

![]() Inside Track Cabling is fully certified to use the Underwriters Laboratories approved logo on our products. Underwriters Laboratories (UL) is an independent product safety testing and certification organization. The UL Mark on a product means that it has been tested by UL and determined to meet UL’s requirements and compliance with U.S. (UL) safety standards. As a manufacturer of UL certified products ITC must demonstrate compliance with the appropriate safety requirements, many of which are developed by UL. ITC must also employ and maintain a program to ensure that each copy of the product complies with the appropriate requirements. UL conducts periodic, unannounced follow-up inspections at our facility to verify and ensure ongoing compliance. If a product design is to be modified, a representative example must be retested before a UL Mark can be attached to the new product or its packaging. http://ul.com/

Inside Track Cabling is fully certified to use the Underwriters Laboratories approved logo on our products. Underwriters Laboratories (UL) is an independent product safety testing and certification organization. The UL Mark on a product means that it has been tested by UL and determined to meet UL’s requirements and compliance with U.S. (UL) safety standards. As a manufacturer of UL certified products ITC must demonstrate compliance with the appropriate safety requirements, many of which are developed by UL. ITC must also employ and maintain a program to ensure that each copy of the product complies with the appropriate requirements. UL conducts periodic, unannounced follow-up inspections at our facility to verify and ensure ongoing compliance. If a product design is to be modified, a representative example must be retested before a UL Mark can be attached to the new product or its packaging. http://ul.com/

CSA Recognition:

![]() Inside Track Cabling is a recognized manufacturer of products which meet applicable CSA product safety and quality assurance standards. Established in 1919, the Canadian Standards Association (CSA) is an international leader in safety and quality standards testing. The CSA is a division of the CSA Group. Its mark appears on millions of products sold annually throughout the world. It is required by law for many products sold within U.S. and Canadian markets, where the mark tells consumers that the product meets or exceeds CSA’s standards for safety and performance. CSA develops product safety and performance standards including those for electrical and electronic equipment, industrial equipment, compressed gas handling appliances, environmental protection, and construction materials. CSA is composed of representatives from international industry, http://www.csagroup.org

Inside Track Cabling is a recognized manufacturer of products which meet applicable CSA product safety and quality assurance standards. Established in 1919, the Canadian Standards Association (CSA) is an international leader in safety and quality standards testing. The CSA is a division of the CSA Group. Its mark appears on millions of products sold annually throughout the world. It is required by law for many products sold within U.S. and Canadian markets, where the mark tells consumers that the product meets or exceeds CSA’s standards for safety and performance. CSA develops product safety and performance standards including those for electrical and electronic equipment, industrial equipment, compressed gas handling appliances, environmental protection, and construction materials. CSA is composed of representatives from international industry, http://www.csagroup.org

IPC/WHMA-A-620:

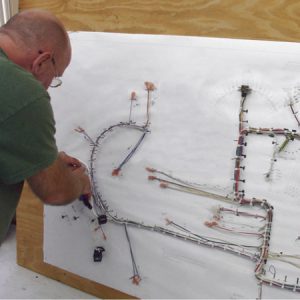

![]() Inside Track Cabling manufactures all of its products to the current IPC/WHMA-A-620B standard. Since its debut in 2002, the IPC-WHMA-A-620 standard for the acceptance of cable and wire harness assemblies enjoyed almost immediate international acceptance, and it quickly became the most important process, materials and inspection document in our industry. The standard was jointly developed by the Wiring Harness Manufacturers Association(WHMA) and the IPC-Association Connecting Electronics Industries. Revision A of the standard, published in July 2006, contained a number of refinements related to harness testing. In preparing the current Revision B of the A-620 standard published October 1, 2012, the WHMA and the IPC reviewed and resolved more than 400 user comments on revision A. “No chapter has been untouched, from minor wording changes to major overhaul,” states Lyle Fanning, WHMA chairman and former president. “The new revision also contains more than 100 new or updated pictures and illustrations.” The A-620 standard is being followed by harness assemblers in 42 countries and has been translated into seven languages: English, Chinese, German, Danish, French, Polish and Spanish, http://www.ipc.org

Inside Track Cabling manufactures all of its products to the current IPC/WHMA-A-620B standard. Since its debut in 2002, the IPC-WHMA-A-620 standard for the acceptance of cable and wire harness assemblies enjoyed almost immediate international acceptance, and it quickly became the most important process, materials and inspection document in our industry. The standard was jointly developed by the Wiring Harness Manufacturers Association(WHMA) and the IPC-Association Connecting Electronics Industries. Revision A of the standard, published in July 2006, contained a number of refinements related to harness testing. In preparing the current Revision B of the A-620 standard published October 1, 2012, the WHMA and the IPC reviewed and resolved more than 400 user comments on revision A. “No chapter has been untouched, from minor wording changes to major overhaul,” states Lyle Fanning, WHMA chairman and former president. “The new revision also contains more than 100 new or updated pictures and illustrations.” The A-620 standard is being followed by harness assemblers in 42 countries and has been translated into seven languages: English, Chinese, German, Danish, French, Polish and Spanish, http://www.ipc.org

ANSI and NIST Traceability:

![]() Inside Track Cabling employs an extensive inventory of state-of-the-art wire/cable preparation and automatic termination centers, wire/cable processing and terminating equipment and wire/cable testing and validation equipment which enable us to produce high quality, high volume product in a fraction of the time of our competitors. The calibration of our equipment is performed in direct accordance with our ISO certified Quality Management System and is traceable to both ANSI and NIST Standards, http://ansi.org

Inside Track Cabling employs an extensive inventory of state-of-the-art wire/cable preparation and automatic termination centers, wire/cable processing and terminating equipment and wire/cable testing and validation equipment which enable us to produce high quality, high volume product in a fraction of the time of our competitors. The calibration of our equipment is performed in direct accordance with our ISO certified Quality Management System and is traceable to both ANSI and NIST Standards, http://ansi.org

FDA / cGMP Compliance:

![]() As a manufacturer of high quality cable and harness assemblies, many of which are utilized within the medical and medical device industry, Inside Track Cabling maintains strict compliance to the FDA Quality System (QS) Regulation/Medical Device Good Manufacturing Practices. Although the QS Regulation applies only to “finished device” manufacturers, ITC operates its facility and manufacturing process in complete accordance with all current FDA/cGMP Standards. ITC Statement of Commitment to FDA/cGMP Standards (PDF)

As a manufacturer of high quality cable and harness assemblies, many of which are utilized within the medical and medical device industry, Inside Track Cabling maintains strict compliance to the FDA Quality System (QS) Regulation/Medical Device Good Manufacturing Practices. Although the QS Regulation applies only to “finished device” manufacturers, ITC operates its facility and manufacturing process in complete accordance with all current FDA/cGMP Standards. ITC Statement of Commitment to FDA/cGMP Standards (PDF)

ITAR Registration and Compliance:

![]() Inside Track Cabling is registered with the U.S. Department of State and is in compliance with the International Trade in Arms Regulations. ITAR registration is required for any U.S. company to manufacture controlled defense articles, defined on the U.S. Munitions List (USML) under the U.S. Department of State, and is a precondition to apply for an export license or exemption. A copy of our Manufacturer Registration Statement is available for your review.

Inside Track Cabling is registered with the U.S. Department of State and is in compliance with the International Trade in Arms Regulations. ITAR registration is required for any U.S. company to manufacture controlled defense articles, defined on the U.S. Munitions List (USML) under the U.S. Department of State, and is a precondition to apply for an export license or exemption. A copy of our Manufacturer Registration Statement is available for your review.

ITC ITAR Manufacturer’s Registration Statement Letter

RoHS and WEEE:

![]() RoHS has become an industry standard. Inside Track Cabling continuously updates its RoHS policies and procedures to ensure complete and accurate fulfillment of each individual customer’s requirement(s). RoHS, also known as Lead-Free, stands for Restriction of Hazardous Substances. RoHS Directive 2002/95/EC restricts the use of six hazardous materials found in electrical and electronic products. All applicable products in the EU market after July 1, 2006 must pass RoHS compliance. RoHS impacts the entire electronics industry. The substances banned under RoHS are lead (Pb), mercury (Hg), cadmium (Cd), hexavalent chromium (CrVI), polybrominated biphenyls (PBB) and polybrominated diphenyl ethers (PBDE). The restricted materials are hazardous to the environment and pollute landfills. They are dangerous in terms of occupational exposure during manufacturing and recycling. Any business that sells applicable electronic products, sub-assemblies or components directly to EU countries, or sells to resellers, distributors or integrators that in turn sell products to EU countries, is impacted if they utilize any of the restricted materials. ITC RoHS and WEEE Compliance Statement (PDF)

RoHS has become an industry standard. Inside Track Cabling continuously updates its RoHS policies and procedures to ensure complete and accurate fulfillment of each individual customer’s requirement(s). RoHS, also known as Lead-Free, stands for Restriction of Hazardous Substances. RoHS Directive 2002/95/EC restricts the use of six hazardous materials found in electrical and electronic products. All applicable products in the EU market after July 1, 2006 must pass RoHS compliance. RoHS impacts the entire electronics industry. The substances banned under RoHS are lead (Pb), mercury (Hg), cadmium (Cd), hexavalent chromium (CrVI), polybrominated biphenyls (PBB) and polybrominated diphenyl ethers (PBDE). The restricted materials are hazardous to the environment and pollute landfills. They are dangerous in terms of occupational exposure during manufacturing and recycling. Any business that sells applicable electronic products, sub-assemblies or components directly to EU countries, or sells to resellers, distributors or integrators that in turn sell products to EU countries, is impacted if they utilize any of the restricted materials. ITC RoHS and WEEE Compliance Statement (PDF)

REACH:

![]() On June 1st, 2007, the European Union Commission (E.U.C.) adopted REACH (Registration, Evaluation, Authorization and Restriction of Chemicals EC 1907/2006) regulating chemicals and their safe use. EC 1907/2006 will continue to be phased in through 2018. The aim of the REACH regulation is to ensure a high level of protection of human health and the environment from chemical substances. Inside Track Cabling (ITC) supports the basic aim of REACH in improving the protection of human health and our environment through the better and earlier identification of intrinsic properties of chemical substances. Inside Track Cabling (ITC) is committed to minimizing the impact of our products on both the public health and the environment that we share. We wish to assure our customers that our products are in full compliance the EU REACH requirement. ITC REACH Compliance Statement (PDF)

On June 1st, 2007, the European Union Commission (E.U.C.) adopted REACH (Registration, Evaluation, Authorization and Restriction of Chemicals EC 1907/2006) regulating chemicals and their safe use. EC 1907/2006 will continue to be phased in through 2018. The aim of the REACH regulation is to ensure a high level of protection of human health and the environment from chemical substances. Inside Track Cabling (ITC) supports the basic aim of REACH in improving the protection of human health and our environment through the better and earlier identification of intrinsic properties of chemical substances. Inside Track Cabling (ITC) is committed to minimizing the impact of our products on both the public health and the environment that we share. We wish to assure our customers that our products are in full compliance the EU REACH requirement. ITC REACH Compliance Statement (PDF)

Made in U.S.A.:

![]() At Inside Track Cabling, we take great pride in producing American-Made products of the highest attainable quality, that reduce our environmental impact while supporting our local and national economies by providing employment to local workers. Our products are manufactured and shipped from, our state of the art production facility located in Hudson, New Hampshire. Inside Track Cabling performs due diligence in determining the compliance of the products that we manufacture with the Federal Trade Commission “Made in USA” Standard. ITC Made in USA Compliance Statement (PDF)

At Inside Track Cabling, we take great pride in producing American-Made products of the highest attainable quality, that reduce our environmental impact while supporting our local and national economies by providing employment to local workers. Our products are manufactured and shipped from, our state of the art production facility located in Hudson, New Hampshire. Inside Track Cabling performs due diligence in determining the compliance of the products that we manufacture with the Federal Trade Commission “Made in USA” Standard. ITC Made in USA Compliance Statement (PDF)

Counterfeit Parts Policy:

![]() Inside Track Cabling is committed to refining and improving our existing Quality Management System and procurement process to effectively address the problem of counterfeit parts in the supply chain. To mitigate the increasingly sophisticated counterfeiting activity in the supply of electronic parts, ITC employs policies and processes based upon a “risk based methodology” which is directly aligned with industry standards. Decisions made in regard to materials and processes are based upon industry studies and internal testing. Risks to products and programs are identified and minimized through the implementation of, and adherence to, the company QMS and Counterfeit Parts Policy. ITC Counterfeit Parts Policy (PDF)

Inside Track Cabling is committed to refining and improving our existing Quality Management System and procurement process to effectively address the problem of counterfeit parts in the supply chain. To mitigate the increasingly sophisticated counterfeiting activity in the supply of electronic parts, ITC employs policies and processes based upon a “risk based methodology” which is directly aligned with industry standards. Decisions made in regard to materials and processes are based upon industry studies and internal testing. Risks to products and programs are identified and minimized through the implementation of, and adherence to, the company QMS and Counterfeit Parts Policy. ITC Counterfeit Parts Policy (PDF)